Value Added Services through Technology

Prototype to Production and Assembly

Micro Facture is a woman-owned, full-service contract manufacturer of small, complex precision machined parts for technologically advanced applications. Services such as project management and electro-mechanical assemblies are also provided. Specializing in parts that require the strictest standards of quality and tolerance In the Aerospace, Medical, Electrical, Military, and Agricultural Industries.

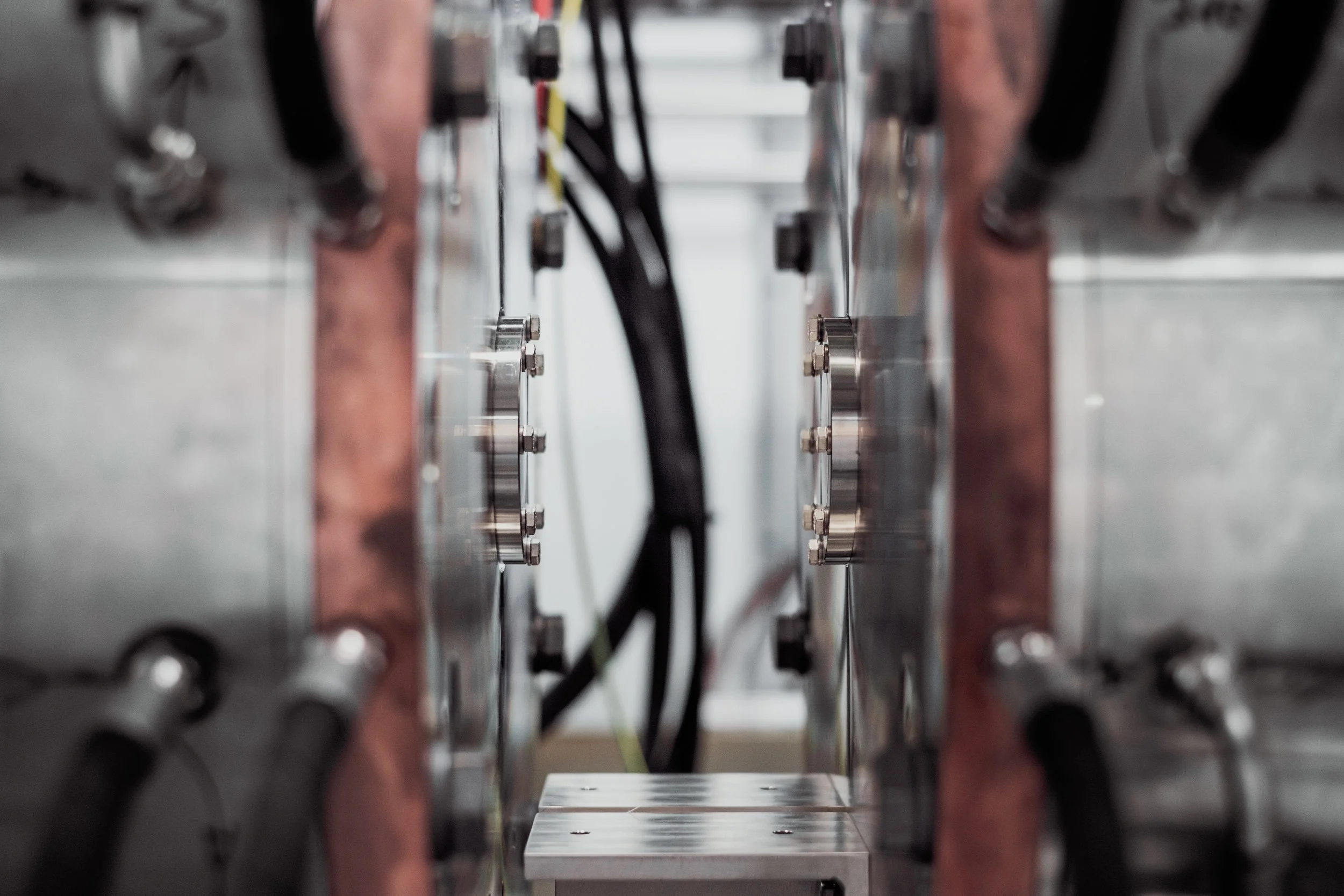

Our 25,000+ square foot production facility features the most technologically advanced equipment available, ensuring dependable operations and consistent part quality. With our pioneering use of robotics, we can effectively produce any quantity with excellent part-to-part consistency. Micro Facture is AS9100 / ISO9001 Certified and complies with the most commonly required Military specifications. We are NIST and ITAR registered and meet ANSI Standards.

a snapshot of who we are

CLICK BELOW TO LEARN MORE ABOUT OUR MISSION, INDUSTRIES WE SERVE, DISTINCTIONS AND CAPABILITIES.

“People Empowered. Legacy Created. Innovation Realized.”